Introduction

ENEA is a scientific RTD organisation with a commitment to sustainable economic development, covering engineering, materials science, chemistry, physics, geology, agriculture, information science, economics, meteorology and biology. Within its Department for Energy technologies and renewable sources, the Laboratory for Energy storage, batteries and hydrogen production and use focuses on the development of advanced processes and components in the hydrogen supply chain, covering power-to-X, hydrogen fuel synthesis, prototyping, system performance and life-cycle sustainability assessment. The sub-laboratory for High-temperature fuel cells and electrolysers operating and testing (HOTLAB), in particular, carries out advanced characterization of solid oxide and molten carbonate cells and stacks: (accelerated) component testing, process identification and optimization. It contributes to the development of international standards in IEC TC105.

Main activities on fuel cells, electrolysers and hydrogen

Main competences and lines of research

- Fast and/or in-depth electrochemical characterization of fuel cell/electrolyser cells and stacks, mainly high-temperature (solid oxide, molten carbonate)

- Performance and durability characterization of high-temperature stacks and components in various conditions, including contaminant testing

- Fuel gas conditioning (clean-up, reforming, separation) for fuel cells

- Power-to-X, Electro-fuel synthesis (methane, methanol, formic acid)

- Thermochemical hydrogen cycles coupled with CSP

- Electric and hybrid (battery/FC) vehicle development and testing

- System modelling of integrated loops for the cement and steel industry

- Lifecycle and sustainability assessment of fuel cell, electrolyser and hydrogen systems

- Study and development of Pd-based membrane technologies for ultrapure hydrogen production and recovery

- Dense metal membranes, typically Pd-based, guarantees ultrapure hydrogen separation since they ensures infinite hydrogen selectivity and high hydrogen permeability values.

- Development of Pd-Ag membranes and membranes reactors for the fuel cycle of fusion machine to recover and purify the un-burned hydrogen isotopes (D and T) and the tritium produced in the breeder blanket.

- Pd-Ag membranes find applications also in fields, other than fusion, in which ultrapure hydrogen is required (i.e. PEM fuel cell, etc.).

- Implementation of several activities to produce ultrapure hydrogen from ethanol, biomasses, olive-mill waste water, etc. via Pd-Ag membrane reactors.

Relevant national/European projects ongoing or concluded

International

- Global Research Laboratory agreement with the Korean Institute for Science and Technology (KIST) 2012-2018

European:

- AD ASTRA: FCH-JU Grant 825027

- WASTE2WATTS: FCH-JU Grant 826234

- BLAZE: HORIZON2020 Grant 815284

- BALANCE: HORIZON2020 Grant 731224

- WASTE2H2: HORIZON2020 Grant 952593

- COMETHY: FCH-JU Grant 279075

- HyLaw: FCH-JU Grant 735977

- INNOSOFC: FCH-JU Grant 671403

- NELLHI: FCH-JU Grant 621227

- qSOFC: FCH-JU Grant 735160

- Scored 2.0: FCH-JU Grant 325331

- SOCTESQA: FCH-JU Grant 621245

- MCFC-CONTEX: FCH JU Grant 245171

National:

- Research on the Electrical System financed by the Ministry of Economic Development: research activity on molten carbonate electrolysis

Research infrastructures

- 3 test benches for high-temperature button cells (1-3 cm2)

- 2 test benches for high-temperature single cells (16 – 144 cm2)

- 1 test bench for high-temperature short stacks

- 1 test bench for high-temperature component testing in dual atmosphere

- Potentiostats/galvanostats

- Electrochemical impedance spectroscopy

- SEM-EDS

- EDX

- XRD

- FTIR and UV–Vis-NIR Spectrophotometers

- CARS and Raman microscopy

- Gas Chromatograph/Mass Spectrometer

- Gas Chromatograph/TCD/FPD/FID

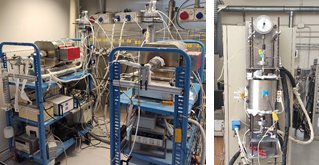

- Two test benches for characterization of single tube membrane reactors.The facilities allow the reactor feeding with a large variety of gas composition and permit its characterization under several operating conditions (i.e. temperature, lumen and shell pressure, vacuum and sweep gas, etc.). Picture of the two test benches for single tube membrane reactors:

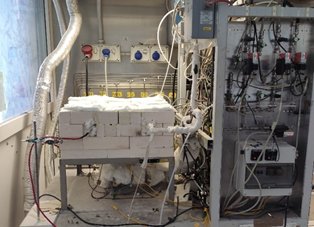

Test bench of a multi-tube permeator. The system allows to study the optimization of the scale-up process for the single-tube membrane technologies. Picture of the design, construction and assembly of the multi-tube experimental facility:

Test bench of a multi-tube membrane reactor. Experimental facility for producing ultra-pure hydrogen (nominal capacity of 1Nm3/h) from the combined reforming of methane and olive mill waste water, realized in the frame of the MICROGEN30 project (bando Industria2015). Picture of a test bench of a multi-tube membrane reactor: