Introduction

“NTNU Team Hydrogen” is a team of world experts on Hydrogen Energy. It is the largest pool of hydrogen researchers in Scandinavia. The team consists of researchers from different disciplines, departments and faculties across NTNU that works within the Hydrogen area. One of the main tasks of the team is to develop new research programs and projects both nationally and internationally with academia, research organisations and industry, and to coordinate Hydrogen activities within NTNU. We are also educating and training research leaders, innovating, providing solutions, and stimulating the industry.

Main activities on fuel cells, electrolysers and hydrogen

Main competences and lines of research

- Material and electrode (CCM, GDE & MEA) development, testing & durability for PEM Fuel Cell (PEMFC), PEM Water Electrolyser (PEMWE) & Alkaline Water Electrolyser (AWE)

- PEMFC/PEMWE/AWE sub-components material development, testing & durability

- PEMFC/PEMWE/AWE stack development, testing & durability

- PEMFC/PEMWE/AWE electrocatalysis development, testing & durability

- Reforming catalysis development, testing & durability

- Hydrogen embrittlement

- Renewable hydrogen

- Hydrogen from natural gas

- Hydrogen from biomass

- Material and system modelling

- System integration

- Hydrogen in maritime, automotive and stationary applications

- Feasilibity studies, cost analyses, life cycle assessment & environmental input-output analyses

Relevant national/European projects ongoing or concluded

International

- Oxygen evolution on nanostructured Ni in alkaline solution (strategic grant with DTU)

- NiO as electrocatalyst for renewable and sustainable electrolytic hydrogen production (SANOCEAN)

- Sonoelectrochemical conversion of biochemicals (SONOELECTROBIO)

- Activity based on NiElectroCAN and CANOPENER collaboration

- Research and demonstration of key technologies for reliable and efficient application of new energy vehicles in China and Norway

- Digitalisation of in the operation, monitoring and control of large-scale biogas plants

European:

- Hydrogen Production by Alkaline Polymer Electrolyte Electrolysis (HAPEEL)

- Next Generation Electrodes for Anion Exchange Membrane Fuel Cells (NEXTGAME)

- Rational design of non-PGM catalyst materials for hydrogen energy (CritCat)

- H2 Coop storage on “Development of tools enabling the deployment and management of a multi-energy Renewable Energy Community with hybrid storage” has received funding from the Smart Energy Systems ERA-Net - Joint Call 2019 on energy storage solutions (MICall19)

National:

- Nickel electrodeposition at Ti electrodes in chloride-based electrolytes (SUPREME)

- Low cost bipolar plates for alkaline water electrolysis (MoZEES)

- Norwegian Fuel Cell and Hydrogen Centre (NFCHC)

- Safe H2 Fuel Handling and Use for Efficient Implementation (SH2IFT)

- Tracking Ångstrøm Nucleation of Thin Films and Nano crystals via Transmission Electron Microscopy

- Micro and nanojoining of Cu to Al using Hy-bond (IN-SANE)

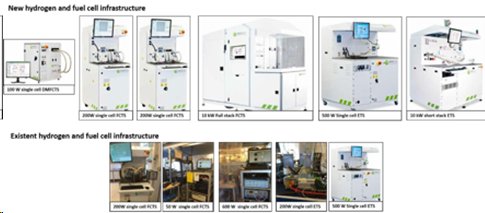

Research infrastructures

- PEM/AEM fuel cell and electrolyser test stations 400-500 W

- DMFC fuel cell test station 40 W

- PEM fuel cell and electrolyser stack test stations 10-12 kW

- SOFC/SOEC 650 W & 6 kW

- Potentiostats/galvanostats

- AC impedance

- Photoelectrochemical devices

- Sonoelectrochemical devices

- Electrochemical FTIR and Raman

- Electrochemical AFM/STM

- ICP/GC/HPLC etc

- DEMS

- UV-vis PMRS

- Microfluidic flow cells

- Scanning Probe Microscope (AFM/STM)

- FTIR spectrometer, UV-vis etc

- Advanced electrochemical equipment (RDE, DEIS, DEMS, EQCM)

- Ultrasonic devices (baths, probes & US-spray)

- “NTNU NanoLab” is one of 4 cleanrooms within "The Norwegian Micro- and Nanofabrication Facility", NorFab

- State-of-the-art physical characterization infrastructure