Main contact

Heathcliff Demaie - heathcliff.demaie@univ-lorraine.fr

Sophie Didierjean - sophie.didierjean@univ-lorraine.fr

Introduction

At UL, 11 laboratories and more than 40 researchers and about 20 PhD students lead activities on hydrogen production, compression and usage from basic science on catalysts and innovative architecture of PEM-FC to issues related to human and social sciences (economics, ergonomics, social psychology, education science). Recently UL gets the support of the French Government through the Excellence Initiative programme (I-SITE Lorraine Université d’Excellence), and is member of Hydrogen Europe Research, KIC InnoEnergy, KIC Raw Materials and of the EUA.

Main activities on fuel cells, electrolysers and hydrogen

Hydrogen production

- Hydrogen production from solar energy by nanostructured perovskites and reduced graphene

- Hydrogen production from biomass by thermolysis or electro-biolysis

- Characterization of aging and operating heterogeneities within a PEM-WE

- Design of a PEM-WE model-based management system

Hydrogen compression and usage

- Synthesis and characterization of PEM-FC electrodes doped with graphene

- Electrochemical and cryo-purification and compression of H2 with bio-sources activated carbons

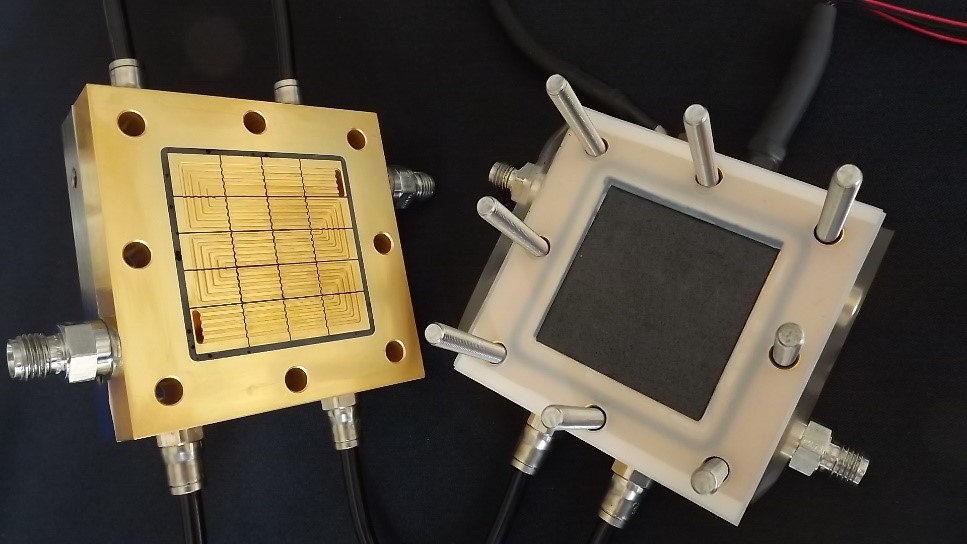

- Analysis of the transport phenomena within a PEM-FC by segmented FC and NMR/MRI

- Degradation and aging of PEM-FC MEA

- Design of a PEM-FC model-based management system

- Direct hybridization of PEM-FC with Super-capacitors

- Power electronics converters for PEM fuel cell management systems and control laws to improve the overall efficiency and to limit the degradation of the electrochemical components

- Innovative design and management technics of micro-grids comprising H2-technologies

To get more information, here is a link to a repository of H2-related publications: https://hal.univ-lorraine.fr/IMPACT-ULHYS/browse/latest-publications

Research infrastructures

10 fully-monitored test benches for low-power PEM-FC or PEM-WEC (mainly mono-cell but also FC stack up to 2kW) able to work 24/7, a test bench for H2 compression up to 700 bar (by electrochemical and cryo-compression) and a spray coating machine to produce electrodes. RMN spectroscopy is also used to monitor membrane behaviour in different conditions

Segmented PEM-FC of 25 cm² - UL/LEMTA