Main activities on fuel cells, electrolysers and hydrogen

Main competences and lines of research:

1) Institute of Electrochemistry and Energy Systems

• Development of gas diffusion electrodes with noble and non – noble catalysts applicable for the hydrogen energy converter devises.

• Development and testing of membrane electrode assemblies or PEM hydrogen fuel cells, electrolysers and unitized regenerative systems

• Design, construction, and system integration; long term performance studies, acceleration tests; degradation phenomena, etc.

• Development of solid oxide electrolytes with mixed ion (proton and oxide ion) conductivity

• Development of innovative design of reversible solid oxide cell with mixed ion conductivity and innovative design with separate chamber for water evaluation/injection

• Development of new approaches for accelerated stress test of solid oxide fuel cells by artificial aging of selected components

• Development of nanostructured electrodes for microbial cells with non-platinum metals as iron, nickel, cobalt chemically deposited on Ni substrate

• Regeneration of metals (Cu, Ag, Au) from wastewater by applying the principle of “microbial electrochemical snorkel”

• Development of new advanced impedance based techniques for testing, monitoring and diagnostics of fuel cells/electrolyzers

2) Institute of Chemical Engineering

• Green hydrogen production with carbon dioxide recycling and wastewater purification for production of chemicals and energy. The developed fuel cell works with wastewater and sodium carbonate/bicarbonate produced from the captured CO2 with final product methanol.

• Utilization of hydrogen sulfide from the Black Sea waters as new energy source operating in an innovative sulfide-driven fuel cell.

• Bio gas production from variety of raw materials (pilot installation)

3) Institute of Polymers

• Laboratory synthesis of basic polybenzimidazoles (meta-, para- and AB-PBI) and chemical modification (e.g. ionomeric derivatization, chemical cross-linking).

• Preparation of PBI-based proton- and anion-conductive ion-solvating and ionomeric type membranes, highly doped with mineral acids (e.g., phosphoric, sulfuric acid), ionic liquids or doped with organic alkali bases (e.g., guanidine, NaOH, KOH).

• Synthesis and preparation of PBI micro- and nanocomposite membranes with incorporated inorganic ion-enhancing and mechanical properties reinforcing fillers (protonated, alkali and organo-modified montmorillonites, carbon fibres and nanotubes, glass fibres etc.).

• Preparation of novel highly volatile alkali PBI based binder solutions, including composite binders with incorporated nanocarbon fillers, fullerenes, metal NPs for direct use in catalyst inks preparation.

• Laboratory preparation of novel electrospun PBI and nanocomposite nanofibrous mats for potential use in intermediate and gas diffusion electrodes preparation.

• Carbonization of PBI materials and synthesis of novel N-doped nano- and mesoporous carbon materials with potential use in electrocatalyst area.

Relevant European/National projects ongoing or concluded

European:

• AD ASTRA: FCH-JU GA 825027

• NET_Tools: FCH JU 736648

• HyLaw: FCH-JU GA 735977

• ENDURANCE: FCH JU GA 62120

• POLINNOVA, EU FP7 “Capacities – Research Potential” programme; GA 316086

• PASPORT Plan of Action - a Strategic Portal to Research Excellence, GA 204722

• CARISMA: Supporting Energy Systems GA 039041

• NextGenCell: Supporting Energy Systems GA 039041019797

• IProPBio:, Horizon2020

National:

• HITMOBIL Centre of Excellence: GA BG BG05M20P001-1.002-0014

• E PLUS: NSP GA: Д01-214/28.11.2018

• ESHER: Research Infrastructure GA ДО1-385/15.12.2020

RESEARCH INFRASTRUCTURES:

Short description of the research infrastructures used with pictures of them when available

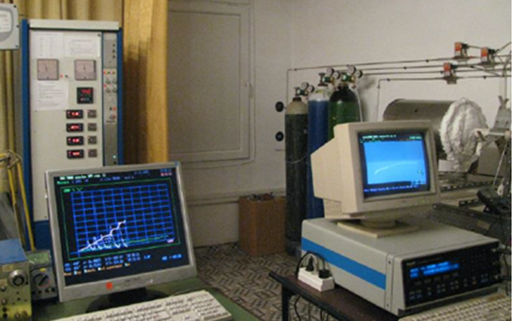

• Test bench with impedance station for electrochemical testing of solid oxide fuel cells/electrolyzers (button cells) with DC power supply of the furnace for improved impedance data quality (own design) combined with methodologies for improved data analysis

• Test bench with impedance station for electrochemical testing of solid oxide fuel cells/electrolyzers (small stacks)

• Laboratory infrastructure for synthesis of solid oxide fuel cells – button cells type (equipment for ball milling, tape casting, screen printing, cold pressing, furnace up to 1400oC)

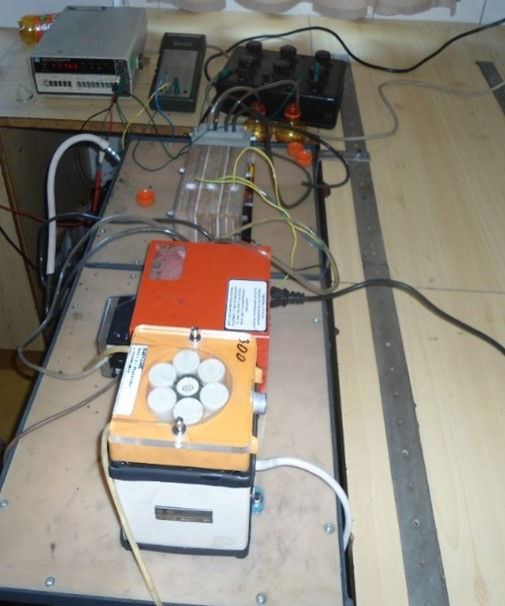

• Equipment for synthesis of catalysts and membrane electrode assemblies (autoclave, ball mill, furnaces, vacuum dryers, ultrasonic baths, microwave, sonificator, automatic film applicator with integrated Dr. Blade and matrix for electrodes up to 50cm2 area, laboratory-designed devices for spray deposition, semi industrial press up to 25 tons and temperature more than 300 C)

• Electrochemical testing Mulii-channelled test stations Gamry 1010E and Gamry 3000 with integrated frequency analyser with booster up to 30A .

• Pilot installation with bio reactor assembly for biogas production from variety of raw materials equipped with Multicomponent analyser for biogas ETG MCA 100 BIO and HPLC-autosampler and RI-detector

• Lab-scale fuel cell stack working with wastewater and sodium carbonate/bicarbonate

• HPLC analytical equipment

•CO2 equipment for supercritical extraction

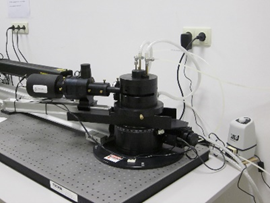

• Integrated impedance measurement system with Potenciostat/Galvanostat model PGSTAT204FRA32M AutoLab® with a Fumatech® MK3 measurement cell for determination of the electron- and ion conductivity of polymer materials.

• Mechanical testing equipment HZ-1005B, 2010 and INSTRON 3344 for mechanical characteristics of polymeric materials and nanomaterials (tensile strength, compressive and bending strength; Young`s modulus and modulus of deformation; maximum elongation at break).

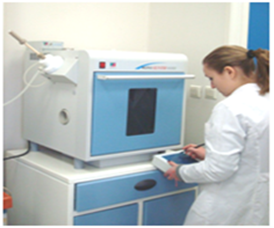

• X-ray diffractometer D8 Advance ECO of Bruker AXS

• HPLC/SEC chromatograph with refractometric and DAD detector Waters Alliance GPC + Wyatt T-rEX + Wyatt HELEOS Ii. Shimadzu Nexera XR LC-20AD HPLC/GPC System

• Dynamic Mechanical Analyzer DMA Q 800, TA Instruments for determination the viscoelastic properties of the material as a function of temperature (-150°C to 600°C) or frequency (0.01Hz to 200Hz).

• Research Goniometer and Light Scattering System BI-200SM - Brookhaven Instruments for static light scattering (SLS) and dynamic light scattering (DLS)

• Microwave reactor RotoSYNTH (Milestone s.r.l.), Rotative Solid-Phase Microwave Reactor with ATC-FO (Milestone)

• Mini Spray Dryer В-290 Аdvance with module for organic solvents, model Inert Loop B-295, BUCHI